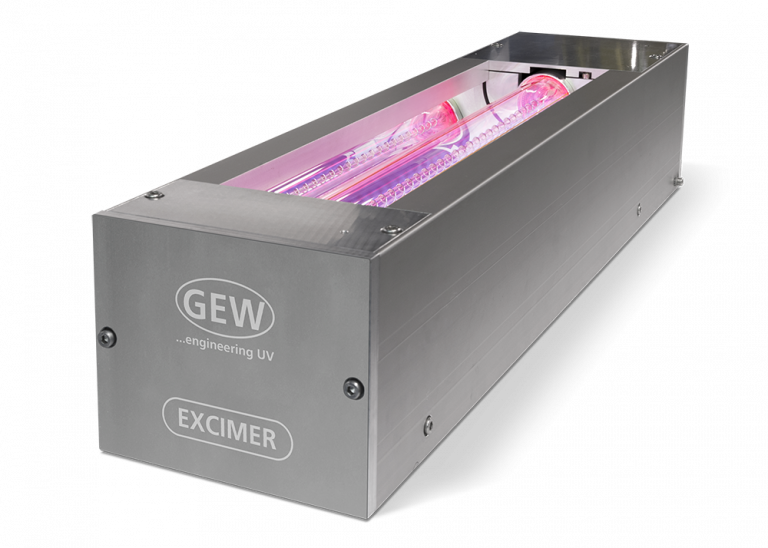

System EXC®

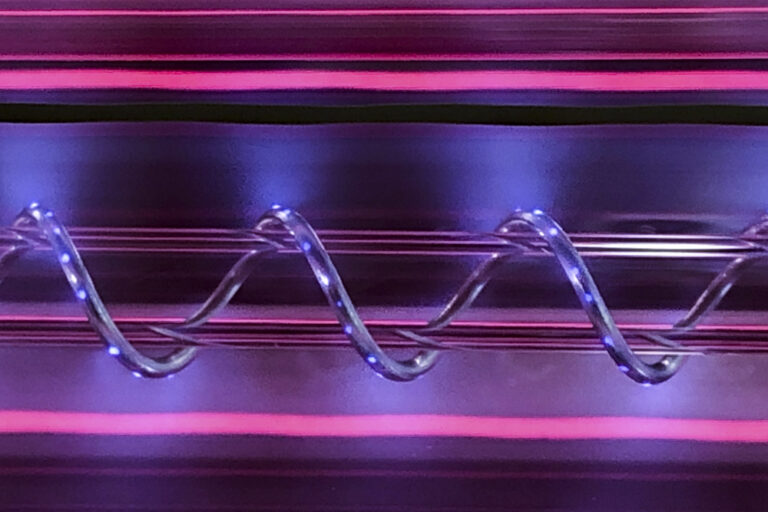

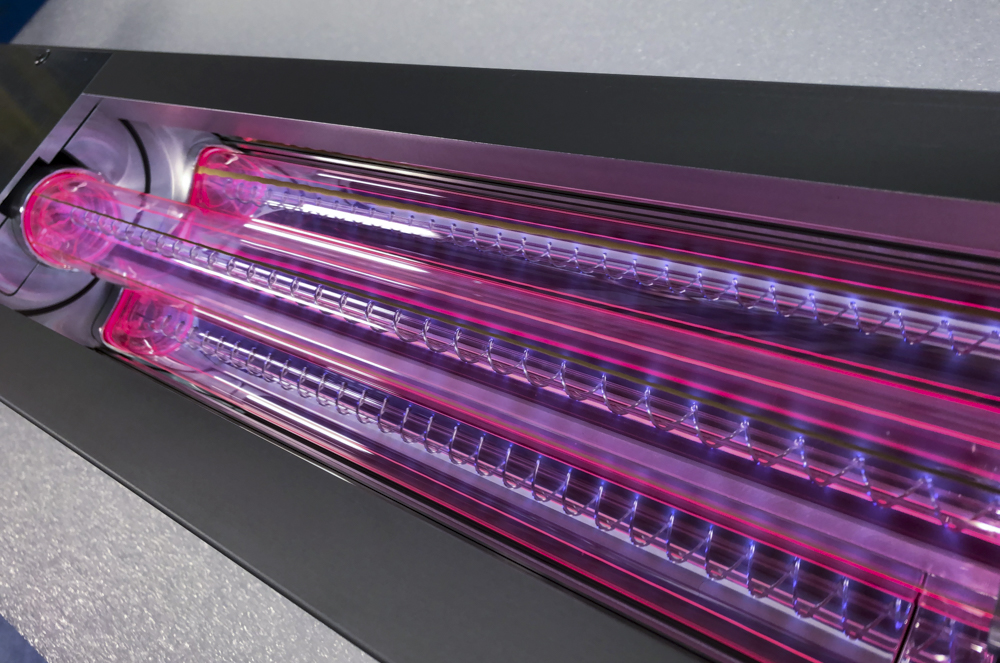

GEW’s EXC lamp systems utilise dielectric barrier discharge (DBD) lamps to produce quasi-monochromatic vacuum ultraviolet radiation, typically at 172nm. This radiation is commonly used for mattification of surface coatings, modification of surface tension for improved adhesion or surface cleaning for semiconductor and medical industries.

GEW EXC lamps can be produced from 12-230cm and can be custom integrated for your specific application including provision for all required nitrogen inerting and control. They are also seamlessly integrated into the wider GEW UV systems which may be required for gelling or post-cure so that GEW can provide a turnkey curing/cleaning solution for your process. Our experienced engineers also ensure rigorous adherence to international safety standards.

Why you should choose the LeoLED® Offset System?

Mattifying

- On/off instantaneous matting

- Additive free coatings for increased durability and process simplification

- Gloss levels >2 G.U.

- Fully integrated into pre-gelling and final cure UV system

- Cleaning

- High efficacy cleaning on a wide range of semiconductor substrates

- Non contact

Surface modification

- Significant increase in surface energy

Cold process for heat-sensitive materials

Low energy, high-efficiency UV generation (up to 40%)

EXC Specification

Max electrical power

5W / cm

Peak wavelength

172nm*

*222nm & 308nm available on request

Irradiance at focal point

30W / cm²*

Maximum length

230cm

Standard cross section

164mm (W) x 130mm (H)

Cooling

N₂ / Air

Standard max operating temperature

40°C (104°F)

Standard max humidity

Non-condensing