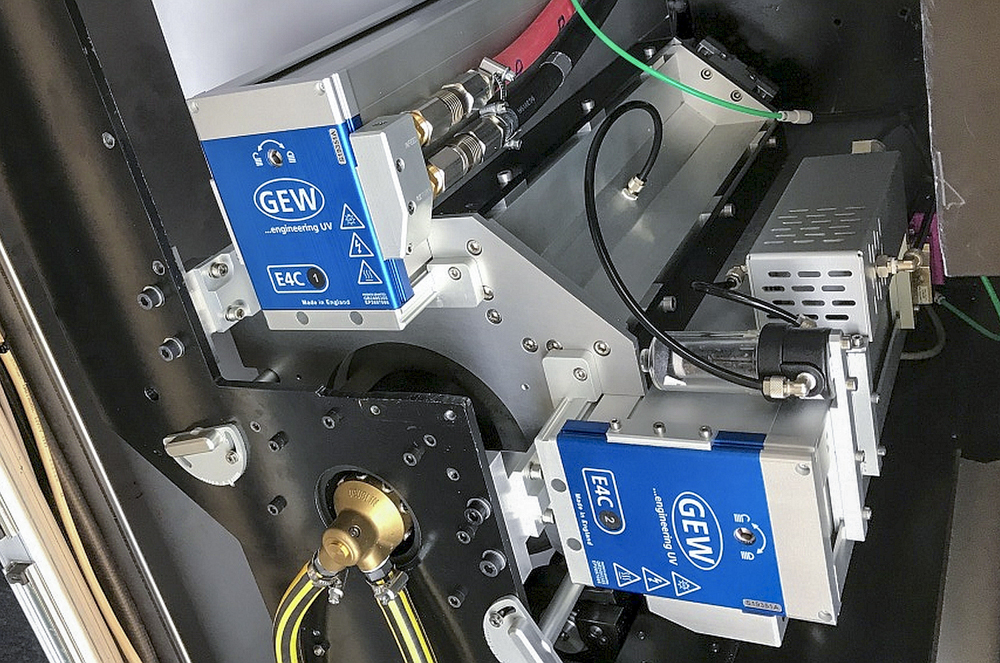

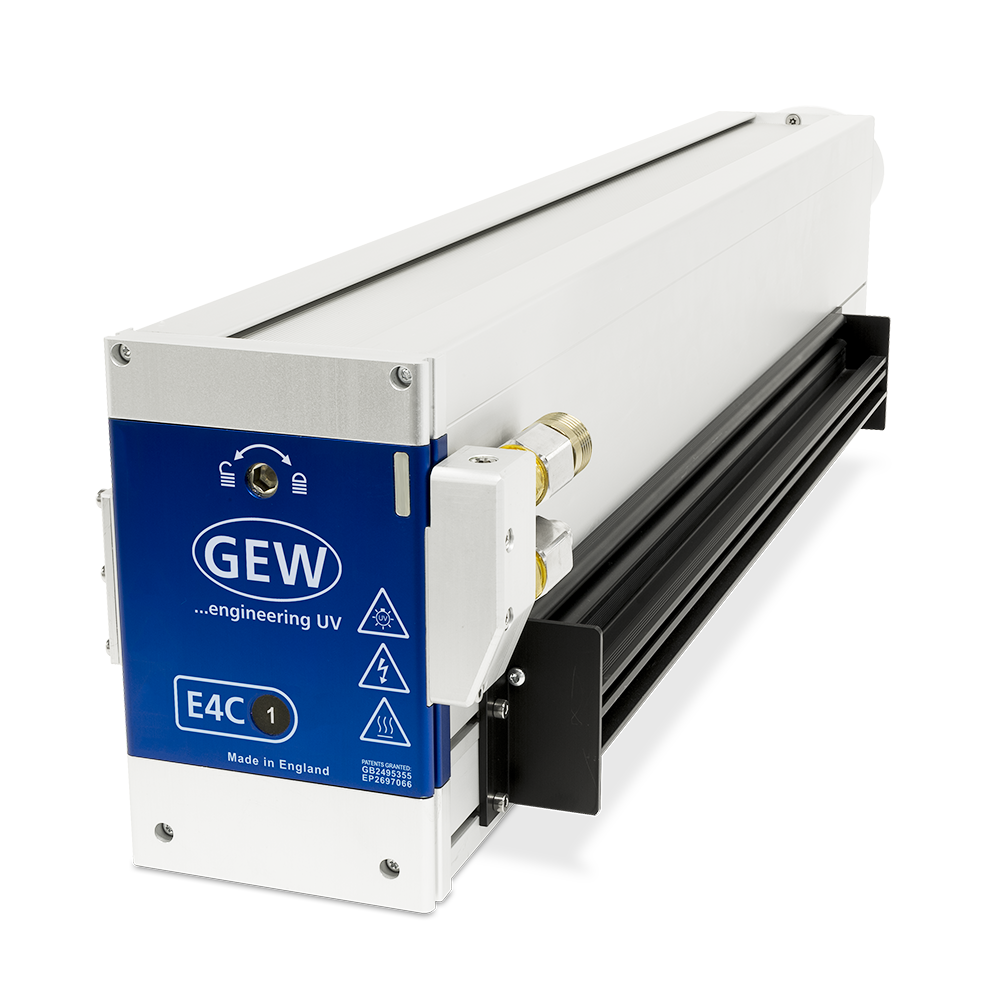

System UV E4C®

E4C offers the highest power available from the GEW range, to support the most demanding UV curing applications and the fastest printing speeds on web or sheetfed machines. It performs to the harshest cure test procedures and is suitable for low migration applications.

E4C has optically tuned reflectors to maximise curing power and operates quietly, with minimal air requirements. An integrated flow switch ensures water flow at all times, and the E4C’s water-cooled reflectors support the highest UV power whilst limiting heat transfer to the substrate, making it safe for a broad range of heat-sensitive materials.

It is designed to operate with the lowest level of maintenance and is engineered for fast, easy lamp changes. All replaceable components are plug-and-play, and the reflectors can be cleaned and fully replaced without breaking the water seals. Furthermore, the reflector mechanisms and seals are tested to millions of operations to ensure reliability.

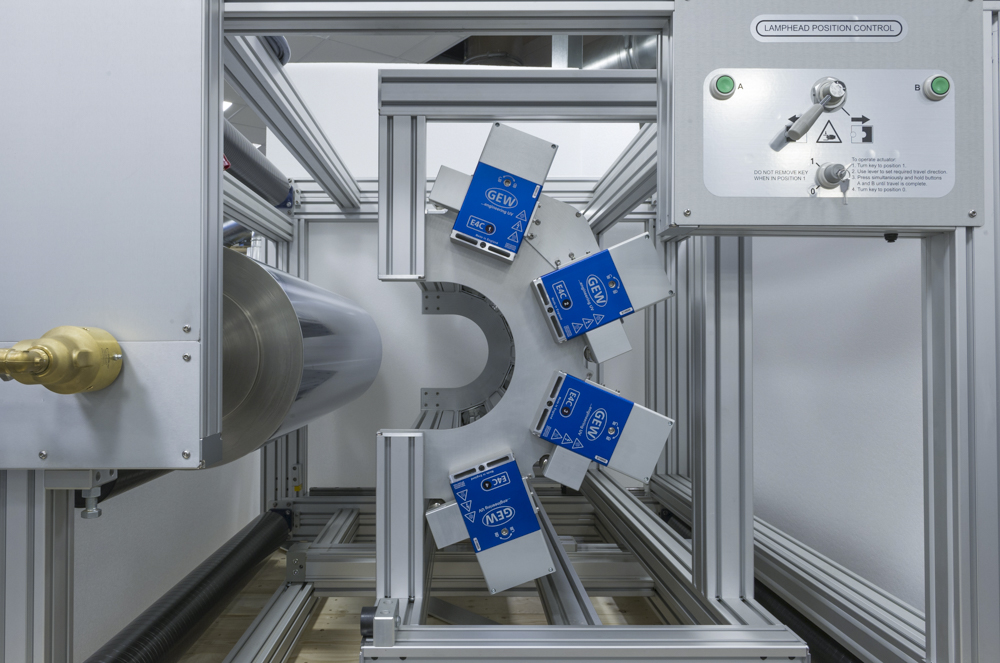

E4C is also LED-ready: its hybrid lamp casing can house either LED, E2C or E4C arc lamp cassettes. It has a compact profile to fit the widest range of machines and is retrofittable on all E2C installations.

Why you sholud choose E4C® System?

Highest power

- High powered, standard profile lamp for Low Migration applications

- Supports the most demanding applications and fastest printing speeds

- Performs to the harshest cure test procedures

Maximum machine productivity

- Fast start lamp technology

- System proactively avoids unplanned downtime

- Consistent, high-speed curing

- Quick to install

Available with multi-point UV monitoring

- Attain 100% UV inspection for every batch

- Improve compliance to European food contact packaging regulations

- Easily see when UV lamps reach end of life

Available with inert atmosphere curing

- Enables production of silicone release liners and food packaging

- Process consistency assured with embedded precision oxygen level control

- Fully engineered solutions designed to suit your specific application

LED-ready

- Upgrade easily to UV LED curing in future by using the same RHINO ArcLED hybrid power supply

Retrofittable

- Compact design allows fitting to the widest range of machines

- Retrofittable on all E2C installations

5-year warranty

- Safeguards against unplanned maintenance costs

Max electrical power

220W / cm

Spectrum

Mercury**

**Lamp variants available on request.

Irradiance at focal point

10.7W / cm²*

*Measured under standard GEW lab conditions with a standard lamphead configuration.

Typical dose @ 100m/min

220mJ/cm2*

Maximum length

170cm

Standard cross section

110mm x 190mm

Cooling

Air and water

Standard max operating temperature

40°C (104°F)

Standard max humidity

Non-condensing

RHINO Power supply

Fail-safe operation

Military-grade design protects the UV system from damage caused by incorrect voltage, short-to-ground, dropped phases, mains spikes and lightning strikes. In the event of a serious mains disruption, the system powers down in a safe mode. RHINO is designed to run in the harshest conditions and at ambient temperatures of up to 40°C. The system is unaffected by dust, ink mist and other contaminants.

Lowest operating costs

With intelligent power management the current draw is balanced and harmonic distortion is minimised, reducing energy demand.

Minimal footprint RHINO Rack

A compact cabinet houses power supplies for up to 6 lamps and provides perfect cooling, atmospheric protection and mains power distribution.

5-year warranty available

Using GEW’s embedded service package gives total confidence in the reliability of GEW power electronics and minimises unplanned maintenance costs. GEW is the only UV supplier to offer this level of warranty.

Control

Embedded service

Using GEW’s embedded service package gives total confidence in the reliability of GEW power electronics and minimises unplanned maintenance costs. GEW is the only UV supplier to offer this level of warranty.

System performance reports

Regular reports are generated, detailing energy usage, uptime percentage and system performance. The Event Log continually records system use and operating parameters, ensuring the system is working at peak efficiency at all times.

Energy performance measurement

The RHINO control automatically logs energy use and displays it on screen at the touch of a button, showing kWh consumption in operation, at idle and % production uptime.